Nepalese food sector is a very wide sector consisting of various types of industries such as sugar, flour mills, vegetable oil and ghee, noodles, biscuit, dairy, rice mills, beverage, confectionary, etc. This article considers only sugar industries as one represenatation of the food sector having huge energy saving potentials. Presently, the Sugar industries are producing white plantation sugar as main product, while baggasse and molasses are also produced in considerable quantity as valuable byproducts. Molasses is used as raw material for Spirit production and the bagasse is used by the industries as a primary energy to produce electricity as well as heat energy (GIZ/NEEP, 2012).

At present there are five large sugar mills in operation. Including around 50 small scale raw sugar producing units (so called “Khandsari) Nepal’s sugar sector provides employment to 3,432 persons and has a value of output of NPR 3.279 Billion against the input of NPR 2.864 Billion and value addition of NPR 0.415 Billion (CBS, 2006).

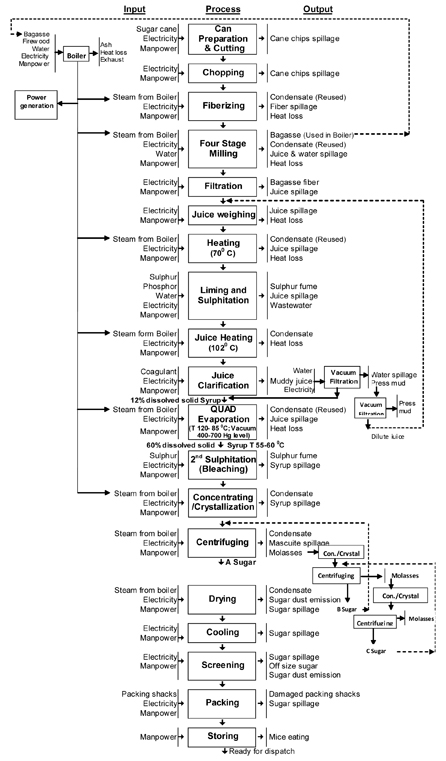

Process

The major processes involved in the production of sugar are

- Milling (Juice Extraction),

- Evaporation,

- Crystallization and Centrifugal separation and

- Washing of the crystallized sugar.

Process flowchart of a sugar mill

Energy Use

Sugar industries in Nepal are operational for nearly 3 to 4 months a year during the cane harvesting season (generally from December to March).

Main source of energy used in the Sugar industries in Nepal is bagasse which is a by-product of the sugar processing. Bagasse is used as fuel high pressure steam turbine to generate electricity that is mainly used for operation of different electrical drives and equipments. Electricity supply from utility company is only used for lighting and carrying out operation and maintenance work. Thermal energy is required for the operation of high pressure boilers that are also using the bagasse as fuel. All sugar mills have their own Diesel Generator set to supplement the power supply mainly for the lighting and maintenance purposes during power failure from the central grid.

| Specific Energy Consumption per ton of product | |

|---|---|

| Electrical | Thermal |

| 68.50 kwh/ton | 128.53 MI/ton |

Heavy motors are used in sugar industries for crushing, pumps, fans, compressors and other motors. Sugar mills use old and rewound motors. The industries have not checked their motor loadings and not carried energy audit in the industries. All the mills have installed capacitor banks to improve the power factor. One of the sugar mills has surplus turbine capacity and this can be readily utilized for the supply of electricity to grid by co-generation.

Major energy consuming sections and equipment in Nepal’s Sugar mills are:

- Cane preparation

- Milling

- Evaporators

- Centrifuging

- Boilers and Co-generation plant

- Electrical Distribution transformer & Power systems

- Electrical drives

- Compressors

- Lighting system

- Material handling equipments.

References

- GIZ/NEEP, 2012: Baseline Study of Selected Sector Industries to assess the Potentials for more efficient use of energy.

- Central Bureau of Statistics (CBS), 2007: Census of Manufacturing Establishments carried out in the fiscal year 2006/07.