Boiler is an enclosed pressure vessel that provides means for combustion heat to be transferred into water until it becomes hot water or steam. The hot water/steam under pressure is then usable for providing heat for an industrial process.

Depending on the type of boiler different forms of fuel or energy used are coal, diesel oil, furnace oil, rice husk, firewood etc.

Design and Operation

A boiler system comprises three parts:

- A feed water system

- A steam system

- A fuel system.

The feed water system provides water to the boiler and regulates it automatically to meet the steam demand. The steam system collects and controls the steam produced in the boiler. Steam is directed through a piping system to the point of use. Throughout the system, steam pressure is regulated using valves and checked with steam pressure gauges. The fuel system includes all the equipment used to provide fuel to generate the necessary heat.

The heating surface is any part of the boiler metal that has hot gases of combustion on one side and water on the other. Any part of the boiler metal that actually contributes to making steam is heating surface. The quantity of the steam produced is indicated in tons of water evaporated to steam per hour.

Boiler Types and Classifications

There are virtually infinite numbers of boiler designs but generally they fit into one of two categories:

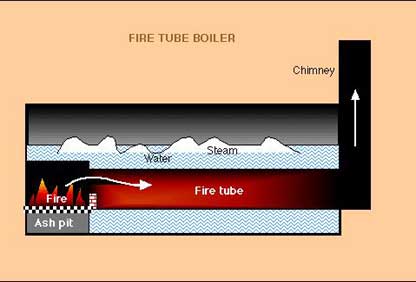

Fire tube or "fire in tube" boilers; contain long steel tubes through which the hot gasses from a furnace pass and around which the water to be converted to steam circulates.

Water tube or "water in tube" boilers in which the conditions are reversed with the water passing through the tubes and the hot gasses passing outside the tubes.

.jpg)

Figure 1: Schematic view of fire tube boiler (left) and water tube boiler (right)

Besides above classifications, boilers are classified also classified based on the number of passes - the number of times the hot combustion gases pass through the boiler, fuel feeding systems, applications, etc.