Description

We, Ekta Engineering & Marketing Pvt Ltd, are mainly in the business of Steam Engineering, Control Instrumentation since last 26 years. We are leading organization in Nepal dealing in these products.

Steam Engineering & Control Instrumentation and Boilers:

We are representative of Forbes Marshall Group – Pune, for Nepal since last 26 years. There are more than 150 process industries as our satisfied valued customers all over Nepal.

We have successfully completed many projects in Steam Engineering & Control Instrumentation line . Hyatt Regency Kathmandu, Pokhara Noodles, Kanchanjangha Noodles, Dabur Nepal, Surya Nepal, NEA are few names. Bottlers Nepal, Balaju, Surya Nepal (ITC Group), Soaltee Crown Plaza, Unilever Nepal, Himalayan Snax, Gorkha Brewery, Nepal Tobacco, Asian Thai Food, Nepal Phamceitical, Maruti Pharma, Magnus Pharma, Nadan Ghee, Ganapati Ghee, Everest Paper & Everest Sugar, Diary Development Corporation, Himalayan Distilleries, Aarati Strips (Bhushan Steel), Reliance Paper are few of our major customers.

We have active strong team for sales & after sales services. All our personnel are trained in both lines. Our technical team led by Mr. Gamvir Man Dangol – Technical Director, is trained & has huge experience for designing steam distribution & control system, supervision of erection & commissioning of Boiler & Steam lines and maintenance job.

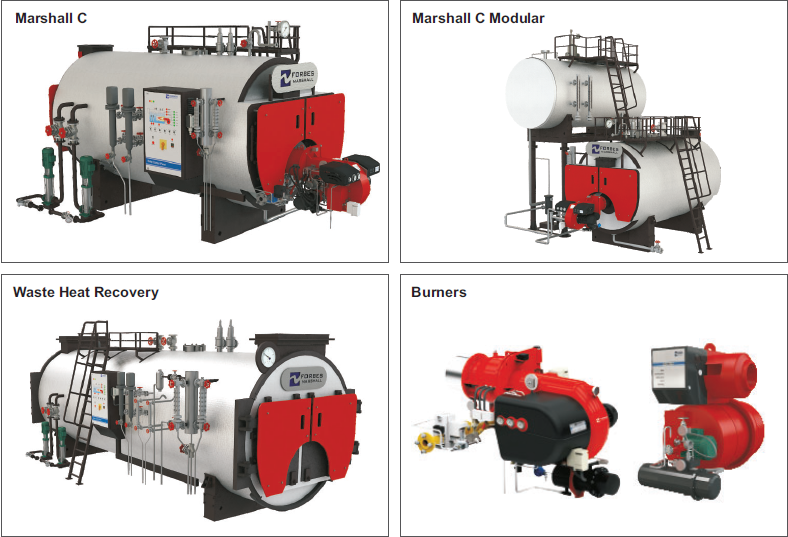

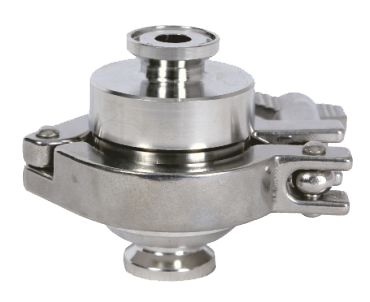

Products 1. Boilers 2. Variable Area Flowmeter 3. Vortex Flowmeter 4. Valves 5. Pressure guage

Supplier Video

Seven Decades of Process Knowledge

Leaders in process efficiency and energy conservation, Forbes Marshall uses its extensive process knowledge to save customers energy, improve efficiency and run a clean and safe factory.

It all began in 1926, when what is now the Forbes Marshall Group started supplying textile accessories to a thriving textile industry in Ahmedabad. Forbes Marshall's focus on energy conservation dates back to our foundation in 1946 when the group entered into the distribution of products for the effective and efficient use of steam for energy. By using these products, process industries, particularly textile mills, could make substantial savings on their fuel bills.

By 1958, the first manufacturing unit was established in Kasarwadi, Pune, with a staff of 12 members. Today, Forbes Marshall has six manufacturing divisions in joint venture with leading international companies and represents several more.

The Steam Systems Division manufactures steam accessories that cover the entire steam and condensate circuit.

In 1962, Forbes Marshall entered the field of control instrumentation by introducing a range of world class pH analysers in a joint venture with Cambridge Instruments UK, to manufacture a complete range of water quality analysers.

Our expertise in steam processing and liquid analysis led to the extension of process media through a joint venture with KROHNE, Germany IN 1984. With them, we began manufacturing a wide range of flow and level equipment and, with the introduction of KROHNE Marshall's Vortex Flowmeter, manufactured products for the world market in India.

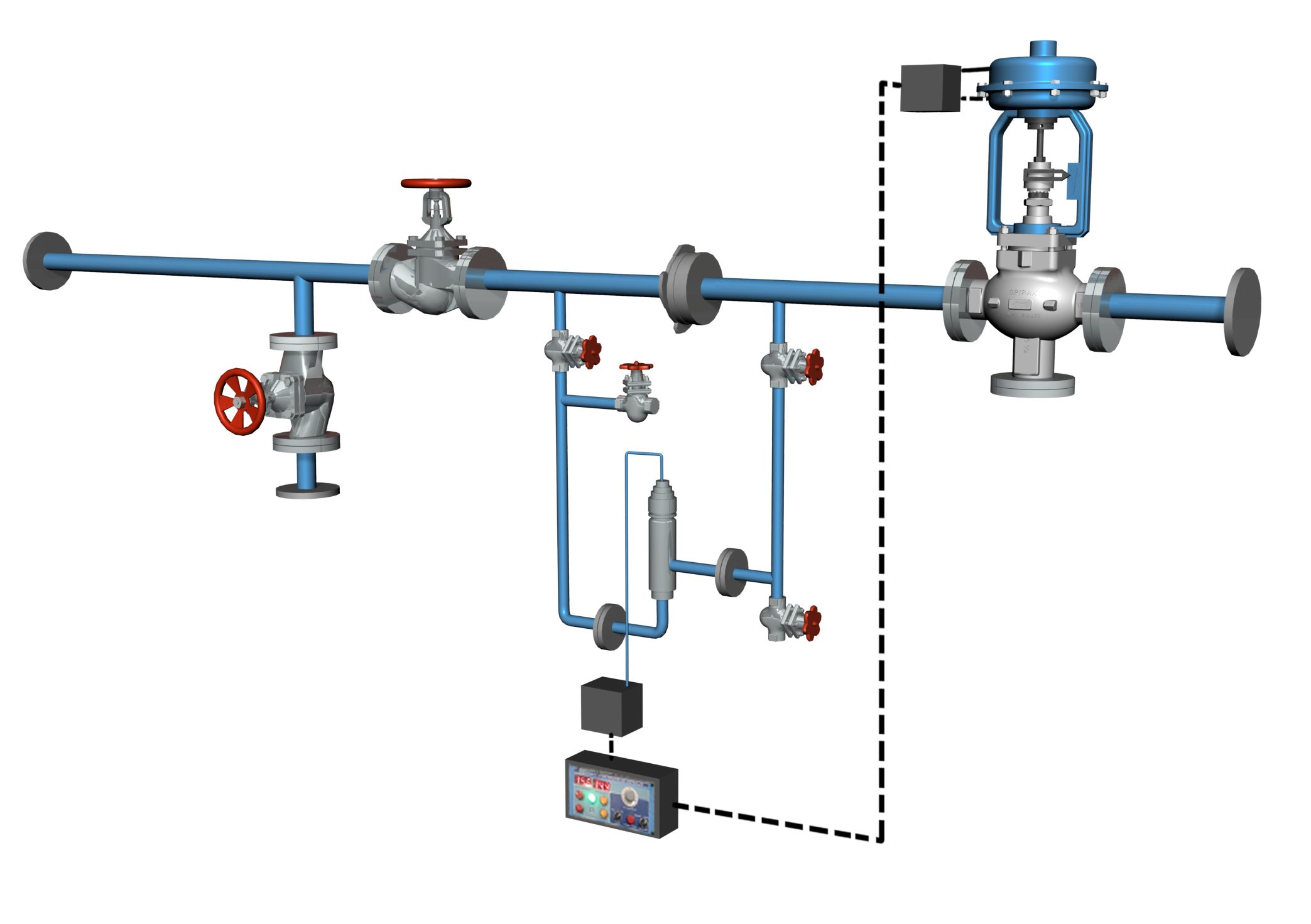

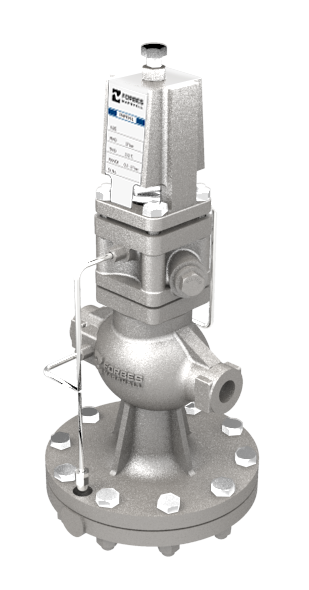

IN 1985, we introduced a range of control valves and de-superheating stations in collaboration with Arca Regler, Germany. These control valves, when used with Forbes Marshall actuators, set a new standard in accuracy and reliability.

In 2007, Forbes Marshall CODEL, a joint venture between Forbes Marshall and CODEL International, UK was incorporated for the manufacture of emission monitoring systems. In 2015, CODEL became a subsidiary of Forbes Marshall

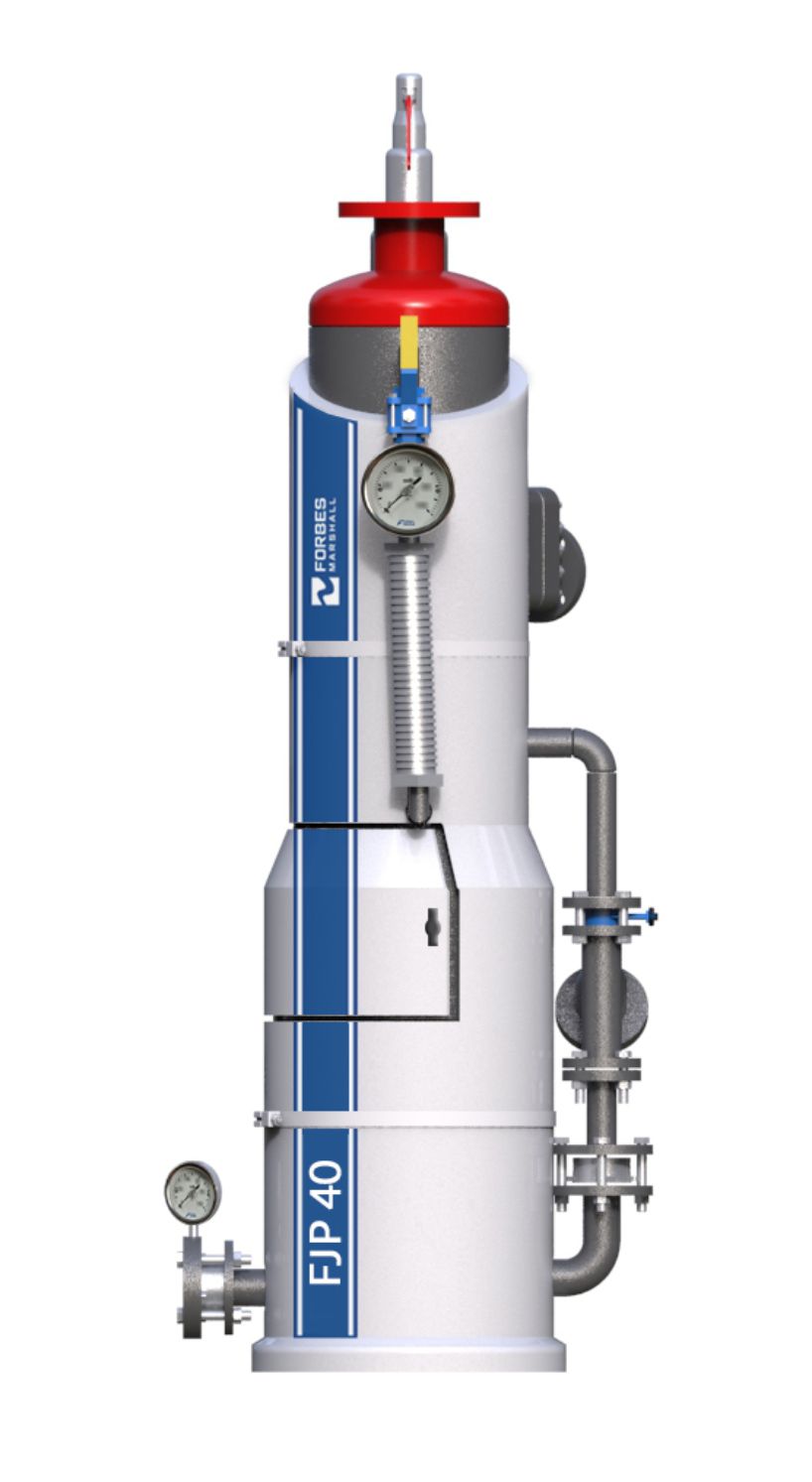

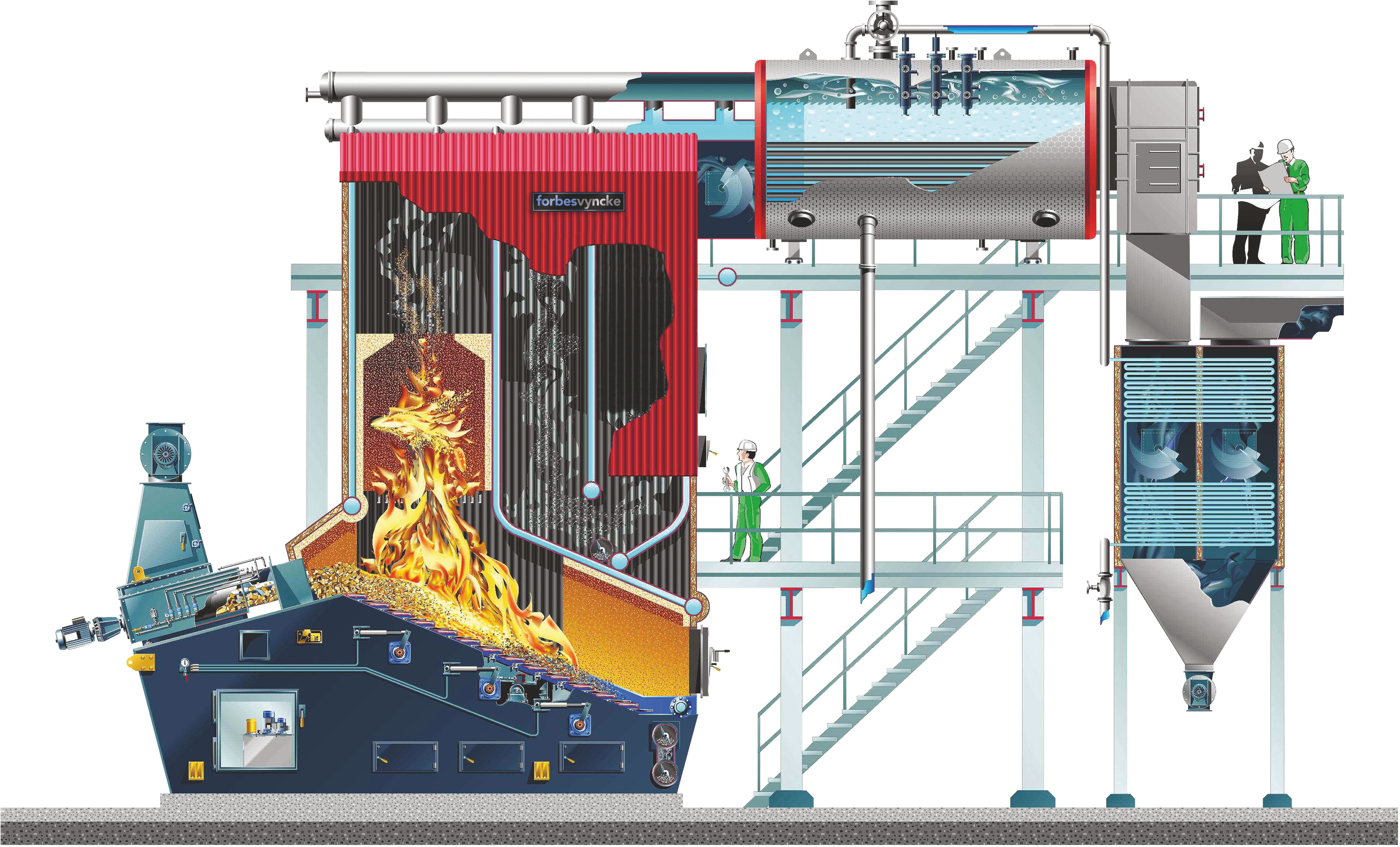

Forbes Vyncke, a joint venture with Vyncke, Belgium, established in 2009 offers Steam, Hot Water Boilers, Thermic Fluid Heaters with patented combustion technologies for Biomass, Coal and Boilers for special fuels like industrial waste and municipal waste and energy plants for the ply industry.

Today, we have 20 sales offices in India and 18 overseas, and 5 manufacturing facilities including one in the UK.

Energy Conservation

Our range of products, solutions and services help bring down the cost of steam throughout the process - from generation, to distribution and utilisation right up to recovery.

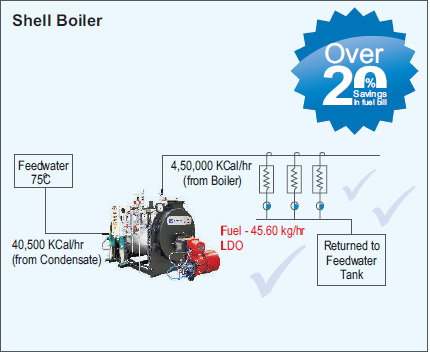

Steam Generation

A Boiler is the heart of a steam system. Fuel cost forms a significant proportion of cost of ownership for both solid and liquid fired boilers. One third of the scope in energy conservation lies is in the boiler house alone. Selection of the right boiler, and optimising operating efficiency, can substantially bring down the running cost of a plant. Our unique range of products, systems and software help you keep track of exactly how much energy you consume and where it goes.

Steam Utilisation

For optimum steam utilisation it is essential to ensure that the steam requirement for any process is monitored and controlled, and condensate is removed as soon as it is formed. We offer a wide range of steam traps and trap monitoring systems for efficient removal of condensate, steam metering, temperature and pressure control systems and waste heat recovery solutions to ensure optimum utilisation of process steam at your plant.

Steam Distribution

The advantage of using steam as a utility is mainly due to the fact that it can be easily distributed and controlled. Typical distribution losses of 3% to 5% as steam travels from the generation end to the utilisation area range need to be minimised. Our range of products ensures that steam distribution is efficient and steam reaches the point of usage at the correct temperature and pressure, and in the desired quantity - steam traps and air vents ensure effective removal of condensate and air; steam flow meters monitor the flow of steam in the distribution network; pressure reducing stations ensure precise control of pressure at the point of usage.

Flash Steam and Condensate Recovery

Hot condensate released from a process typically contains 20% of the heat energy. Some of the condensate flashes into steam known as "flash steam". This flash steam contains about 40% - 55% of the total energy of the condensate. Recovering this energy and result in huge savings in the annual fuel bill. Forbes Marshall has a wide range of application specific solutions – from flash vessels, to condensate recovery pumps to thermocompressor systems - to help maximise condensate recovery and save fuel costs.

Services

Our utility design consultancy and project management services for greenfield plants and expansions focus on designing reliable, safe, energy efficient and easy to operate and maintain utility systems for process industries. Across industry segments plants designed by us have been set up with the most optimised Capex and are operating at the lowest Opex. Our project management expertise enables us to deliver turnkey engineering by providing our technical expertise during erection and commissioning.

Forbes Marshall has a customised audit approach which focuses on improving specific energy consumption benchmarks, delivering generic savings or carrying out troubleshooting of the steam system to address utility related production bottlenecks. Our inherent strengths of engineering and project management enable us to deliver savings. The report includes recommendations to improve benchmarks and deliver savings.

.png)

.png)